Back to: MICROBIOLOGY 400 LEVEL

Welcome to class!

Hello, superstar! It’s always a joy to have you here. I hope you’re feeling great today because we’re about to enter another exciting part of industrial microbiology that connects directly with engineering, technology, and smart design. Our topic is Design and Types of Fermenters, including stirred tank, airlift, and packed bed fermenters. These are the “homes” where microbes do their magic, and the design of each fermenter determines how well your microorganisms perform.

Design And Types Of Fermenters (Stirred Tank, Airlift, Packed Bed)

What is a Fermenter?

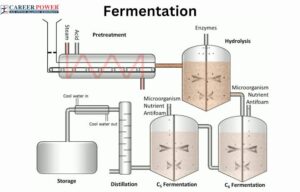

A fermenter is a specially designed vessel or container where fermentation takes place under controlled conditions. Think of it like a greenhouse for microbes—everything from temperature to air supply to nutrients must be just right so that the microorganisms can grow and produce the desired product effectively.

In industrial settings, fermenters come in various shapes and sizes depending on the type of fermentation, the microorganism used, and the product being made. Let’s break it down using simple explanations and relatable examples.

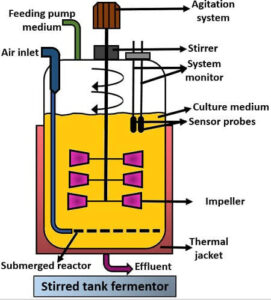

1. Stirred Tank Fermenter (STF)

This is the most commonly used type of fermenter. It looks like a big cylindrical tank with motorised stirrers (impellers) and spargers to introduce air.

Features:

Mechanical stirrers keep the culture well-mixed.

Spargers inject air or gases.

Sensors monitor pH, temperature, and dissolved oxygen.

Example: Imagine cooking ogi in a pot and continuously stirring it to make sure the heat and consistency are uniform. That’s exactly how STF works—ensuring even distribution of nutrients, microbes, and oxygen.

Uses:

Antibiotic production (e.g., penicillin)

Alcohol fermentation

Enzyme production

Advantages:

Good mixing and oxygen transfer

Easy to monitor and control

Works well for bacteria and yeast

Limitations:

High energy cost

Can damage sensitive cells (like some fungi) due to shear stress

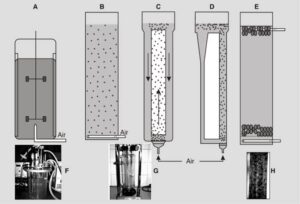

2. Airlift Fermenter

This fermenter uses air or gas to circulate the liquid, without mechanical stirring. It consists of two zones: a riser (where air is added) and a downcomer (where the liquid flows back down).

Features:

Gentle mixing through rising air bubbles

No mechanical stirrer, so less energy is used

Example: Think of how air bubbles rise in a bottle of Zobo drink when you shake it gently. That’s how microbes circulate in an airlift fermenter—using natural upward motion.

Uses:

Cultivating delicate cells like plant or animal cells

Wastewater treatment

Single-cell protein production

Advantages:

Low energy consumption

Less cell damage

Simple design

Limitations:

Less effective mixing compared to stirred tanks

May not be suitable for highly viscous cultures

3. Packed Bed Fermenter

This fermenter is filled with solid support materials like beads, sponge, or agro-waste, and microbes are immobilised on these surfaces. Liquid flows through the packed bed.

Features:

Microbes stay attached to surfaces

Nutrient solution flows over them

Example: Think of how iru (locust beans) are fermented in baskets with banana leaves. The beans (substrate) stay in place while microbial activity happens on their surface—similar to what occurs in a packed bed fermenter.

Uses:

Enzyme production

Vinegar fermentation

Waste treatment systems

Advantages:

High cell density

Reusability of microbial biomass

Low contamination risk

Limitations:

Risk of clogging

Difficult to clean

Not suitable for all types of fermentation

Summary

- Fermenters are vessels designed to support microbial growth and product formation under controlled conditions.

- Stirred tank fermenters use mechanical agitation for good mixing and are ideal for antibiotics and alcohol production.

- Airlift fermenters rely on air bubbles for circulation and are suited for delicate cells and protein production.

- Packed bed fermenters immobilise microbes on surfaces and are good for enzyme and vinegar production.

- Each fermenter has specific advantages and limitations depending on the process and microorganism used.

Evaluation

- Describe one major feature and one major use of a stirred tank fermenter.

- Why might an airlift fermenter be preferred over a stirred tank fermenter for fragile cells?

- What is the main difference between packed bed and submerged fermenters?

Every concept you master brings you closer to becoming a skilled microbiologist with the power to make a difference—from Nigerian industries to global innovations. Keep going strong, and remember, Afrilearn is with you every step of the way. See you in the next class!