Back to: MICROBIOLOGY 400 LEVEL

Welcome to class!

Hi brilliant one! It’s always great to have you here. Your commitment to learning is powerful, and it’s a big part of what will make you an outstanding microbiologist. Today, we’re discussing something very important in industrial fermentation—Control Parameters. These include pH, dissolved oxygen (DO), foam, and temperature. Just like you need the right environment to study—not too noisy, not too hot—microorganisms also need the right conditions to grow well and produce useful products.

Control Parameters (Ph, Do, Foam, Temperature)

What are Control Parameters?

Control parameters are the environmental conditions within a fermenter that must be kept steady and suitable for the microbes. If these factors are not properly monitored and controlled, it can lead to poor product yield or even total fermentation failure. Let’s look at each one in detail.

pH (Acidity/Alkalinity)

pH is one of the most important parameters in fermentation. Microbes have specific pH ranges in which they grow best. For example, Saccharomyces cerevisiae (yeast) prefers a slightly acidic pH (around 4.5 to 5.5), while many bacteria thrive at a neutral pH (around 7).

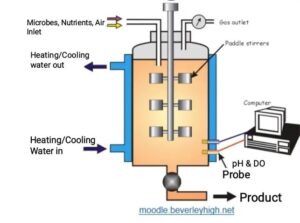

If the pH goes too high or too low, the enzymes inside the microbes may stop working, and cell growth will be affected. In most fermenters, pH is continuously monitored using pH probes, and adjustments are made by adding acid or base to keep it stable.

Dissolved Oxygen (DO)

Many industrial fermentations require oxygen—especially those involving aerobic microorganisms like Penicillium or Bacillus. DO refers to the amount of oxygen available in the liquid for the microbes to use. If oxygen levels drop too low, the microbes may slow down or switch to unwanted metabolic pathways.

To maintain proper DO:

Air or pure oxygen is pumped into the fermenter.

Agitators help spread the oxygen evenly.

Sensors measure DO levels, and control systems adjust airflow or stirring speed accordingly.

Foam Control

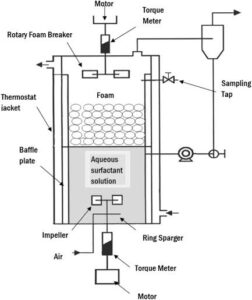

Foam forms when proteins or surfactants in the culture trap air at the surface. This is common in microbial fermentation, especially when there’s a lot of agitation and aeration. Foam can cause several problems:

It leads to contamination risk by spilling over.

It affects oxygen transfer and probe function.

To manage foam:

Antifoaming agents (like silicone oils) are added.

Mechanical foam breakers are sometimes used.

Foam sensors can detect rising foam and trigger defoamer release automatically.

Temperature

Temperature affects everything from enzyme activity to microbial growth rate. Each microorganism has an optimal temperature. For instance, many industrial bacteria grow well at 30–37°C, while fungi like Aspergillus niger prefer slightly lower temperatures.

Too much heat can denature enzymes and kill the cells, while too little slows down metabolism. That’s why fermenters are fitted with temperature control systems—heaters, cooling jackets, and thermostats—to keep things just right.

Summary

- Control parameters ensure that microbes in the fermenter remain in a healthy, productive state.

- pH must be kept within the right range using probes and automatic adjustment.

- Dissolved oxygen is critical for aerobic microbes and is maintained using spargers and agitators.

- Foam is controlled using antifoaming agents or foam breakers.

- Temperature must be stable to support proper microbial activity, using heaters or cooling systems.

Evaluation

- Why is it important to maintain a stable pH in fermentation?

- Mention two ways to control dissolved oxygen levels in a fermenter.

- What are the dangers of foam buildup during fermentation?

You’ve just understood a vital part of what keeps industrial fermentation running smoothly. Remember, you are not just learning facts—you are building skills that can power industries and transform lives. Stay sharp and curious, and always know that Afrilearn believes in you. Let’s keep soaring together!