Back to: MICROBIOLOGY 400 LEVEL

Welcome to class!

Hi there, superstar! I’m so glad to see you here again. You’re doing excellently well. Today, we’re moving into one of the most important stages in industrial microbiology—Separation and Purification of Products. This is the part where we carefully extract and clean up the useful substances that microorganisms produce during fermentation. It’s like cooking soup and then picking out the bones so you’re left with the delicious, edible part!

Separation And Purification Of Products

What is Separation and Purification?

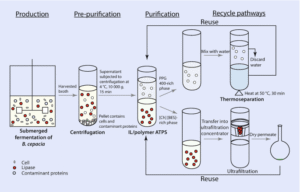

After fermentation, the product we want (like alcohol, enzymes, antibiotics, etc.) is mixed with other substances—like cells, nutrients, waste materials, and by-products. To use or sell that product, we must separate it and purify it to the required quality. This process is also called downstream processing and is just as important as fermentation itself.

Depending on whether the product is inside the microbial cells or outside in the surrounding liquid (broth), the methods used will differ.

Steps in Separation and Purification

1. Removal of Cells (Solid-Liquid Separation)

If the product is secreted into the broth (like ethanol or citric acid), the first step is removing the microbial cells.

Methods:

Filtration: Like sieving garri from chaff. It separates solid particles (cells) from liquid.

Centrifugation: Spins the broth at high speed to separate heavier cells from the liquid. It works like how you spin wet clothes to remove water in a washing machine.

2. Cell Disruption (If the product is inside the cells)

For products like some enzymes or single-cell proteins, we need to break open the microbial cells.

Methods:

Mechanical: Bead mills or high-pressure homogenisers crush the cells.

Chemical: Adding detergents or solvents to dissolve the cell wall.

Enzymatic: Using special enzymes to break cell walls gently.

3. Product Isolation

Now that the product is free from cells, we begin to separate it from other similar substances.

Methods:

Solvent extraction: Like how palm oil is extracted from palm fruit mash—useful for products that dissolve in solvents.

Precipitation: Adding salts or other chemicals to make the product come out of solution.

Chromatography: A special technique that separates components based on how they move through a material—like sorting beans by size.

4. Purification and Polishing

At this stage, the product is concentrated and purified to the needed standard—especially for medical or food-grade use.

Methods:

Ultrafiltration: Uses membranes to separate molecules by size.

Crystallisation: The product forms crystals, which are then collected.

Drying: Final step to remove water and preserve the product, like turning cassava mash into dry fufu powder.

Real-Life Nigerian Example

Let’s say a company in Aba is producing citric acid using Aspergillus niger. After fermentation, they filter out the fungus, extract the citric acid from the broth, and purify it before packaging. Without proper separation and purification, the citric acid could be contaminated and unsafe to use in food or drinks.

Summary

- Separation and purification help isolate the useful product from the fermentation mixture.

- First, microbial cells are removed using filtration or centrifugation.

- If the product is inside cells, they are broken using mechanical, chemical, or enzymatic methods.

- The product is isolated using extraction, precipitation, or chromatography.

- Final purification uses ultrafiltration, crystallisation, or drying to make the product safe and market-ready.

Evaluation

- What is the first step in separating a product from a fermentation broth?

- Name two methods used to break open microbial cells.

- Why is purification important before a product is sold or used?

Every lesson takes you one step closer to becoming an expert who can build, innovate, and impact industries across Africa. Keep learning with confidence—Afrilearn is proud to be part of your journey. See you in the next exciting class!