Back to: MICROBIOLOGY 100 LEVEL

Welcome to class!

You’re right where you’re supposed to be—learning, growing, and preparing to make a real difference in the world. Today’s topic is one you’ve probably already come across in your everyday life, especially if you’ve ever looked at a milk carton or a hospital setting. We’re learning about Pasteurisation and Sterilisation—two powerful ways we keep things safe from harmful microorganisms.

Pasteurisation And Sterilisation

Let’s begin with a quick scenario. You walk into a supermarket in Lagos and buy a bottle of milk. That milk has likely been pasteurised to make sure it’s safe for drinking. Now, imagine a surgeon preparing for an operation. The tools must be 100% free of all microbes—including the strongest ones. That’s sterilisation in action.

Both pasteurisation and sterilisation are methods used to control microbes, but they are different in how they work, how intense they are, and what they’re used for.

Pasteurisation

Pasteurisation is a process that uses mild heat to kill or slow down the growth of harmful microorganisms in food and drinks—especially liquids like milk, juice, and yoghurt—without changing the taste or quality too much.

This process is named after Louis Pasteur, a French scientist who first introduced it in the 19th century to prevent wine and beer from spoiling.

Types of Pasteurisation:

Low Temperature Long Time (LTLT)

63°C for 30 minutes

Used mainly for milk in some small-scale industries.

High Temperature Short Time (HTST)

72°C for 15 seconds

This is the most common method in commercial milk production.

Ultra-High Temperature (UHT)

135°C for 1–2 seconds

Kills more microbes and increases shelf life; used in milk that doesn’t need refrigeration.

Pasteurisation doesn’t kill all microorganisms, but it destroys the most harmful ones (like Mycobacterium tuberculosis and Salmonella), making the product safe for consumption.

Sterilisation

Sterilisation, on the other hand, is the complete destruction or removal of all forms of microbial life—including bacteria, viruses, fungi, and even highly resistant spores.

Sterilisation is necessary in places like hospitals, laboratories, and pharmaceutical industries where absolute microbial control is needed.

Methods of Sterilisation:

Heat Sterilisation

Autoclaving (moist heat): Uses steam under pressure at 121°C for about 15–20 minutes. Very effective and used for surgical instruments and culture media.

Dry heat: 160–180°C in a hot air oven for 2 hours. Used for glassware, powders, and oils.

Chemical Sterilisation

Uses gases like ethylene oxide to sterilise heat-sensitive materials like plastics.

Radiation Sterilisation

Uses gamma rays or electron beams. Useful for sterilising disposable medical tools (like syringes).

Filtration

Used for sterilising heat-sensitive liquids, like vaccines and enzymes. It removes microbes by passing the liquid through a fine filter.

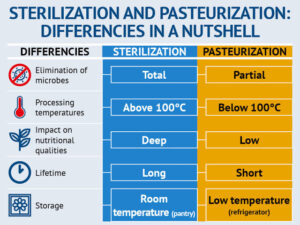

Key Differences

Pasteurisation is for food and drinks; sterilisation is for medical and lab items.

Pasteurisation reduces harmful microbes; sterilisation destroys all microbes.

Pasteurisation uses lower temperatures for shorter times; sterilisation uses higher temperatures or stronger methods.

Summary

- Pasteurisation is a heat process used mainly for liquids like milk to destroy harmful microbes while keeping the product safe and tasty.

- It includes methods like LTLT, HTST, and UHT.

- Sterilisation completely removes or kills all microbes and is essential in hospitals and labs.

- Methods of sterilisation include autoclaving, dry heat, chemicals, radiation, and filtration.

- While pasteurisation ensures food safety, sterilisation ensures total microbial elimination.

Evaluation

- What is the main difference between pasteurisation and sterilisation?

- Name two methods of pasteurisation and the temperatures they use.

- Give two examples of sterilisation methods and where they are used.

Keep showing up for yourself—this habit of learning will take you far in life. Afrilearn is proud to be part of your academic journey. Keep your head high, your spirit strong, and your notebook ready—more exciting lessons await you in the next class!