Back to: BASIC TECHNOLOGY JSS3

Welcome to class!

In today’s class, we will be talking about the processing of wood. Enjoy the class!

Processing of Wood (Defects, Manufactured board)

Defects in Timber

A defect is any feature that reduces the quality and market value of timber. Defects in timber are caused by bad felling, poor seasoning or attack from insects and fungi.

Types of defects in timber

These defects are grouped into two viz:

- Natural defects

- Artificial defects

Natural defects:

These are defects which occur during the growth of a tree. They include the following:

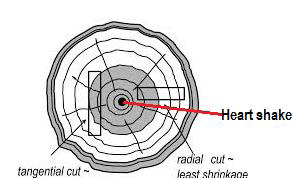

1. Heart shakes: This is a split that is restricted to the pith or centre of a tree.

2. Star shakes: This is similar to the heart shake, but with more splits like a star.

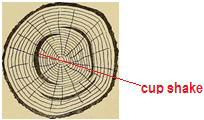

3. Cup shakes: These are visible cracks that go part around the growth ring.

4. Ring shake: This is the circular crack on the timber.

5. Discolouration may be caused by fungus attack in wood with high moisture content.

6. Knot: A knot is a defect that occurs at the branch of a tree. When a knot rots away and falls out of its position, it leaves what is known as knothole.

Artificial defects:

The artificial defects in timber are those defects that are caused by careless handling and faulty seasoning and preservation of wood. They include:

- Cup: This is a concave curvature across the face of the timber. It is caused by bad stacking and shrinkage during drying.

- Bow: This is either concave or convex curvature along the length of a plank.

- Check: This is longitudinal opening or separation of wood along the grain of a plank.

- Twist: This is a spiral form of distortion along the length of a plank.

- Warps: Twists in timber are called warps. They may be caused by improper seasoning procedure.

Manufactured Board

Manufactured boards are man-made wood products that vary in size, weight and structure.

Veneer:

A veneer is a thin sheet of wood used in the manufacture of boards. It is usually sliced from a log.

Methods of producing veneers

(i) Slicing Method: The method of using a slicing blade to cut off thin leaves from a particular log.

(ii) Reeling method: This is the method of peeling log in a continuous rotary fashion mounted on a machine. The log is usually softened through steaming first.

(iii) Eccentric or Sawing Method: In this method, the log is cut into quarters. It is this quarter that is then sliced to veneer.

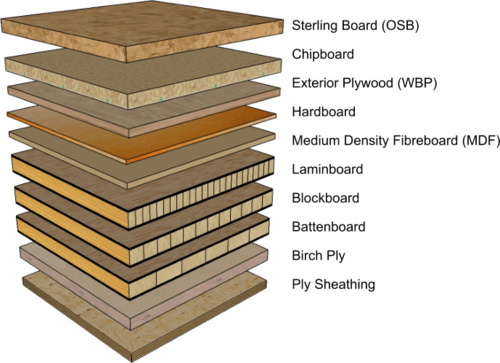

Types of manufactured board

- Plywood: This consists of a product obtained by glueing three or more sheets of veneer together. They are used for partitioning.

- Blockboard: This board looks like a flush door. The inner part of this board contains a strip of timbers forming the core and covered with two layers of veneers. They are used for flooring and doors.

- Laminated boards: These are boards used for high-class veneer furniture. It contains a thinner strip of timber forming the core and glued together. The surface is glossy. They are used for high-class furniture work.

- Particleboards: These are boards made from wood chippings glued together and compressed under heat. It is used for panelling and kitchen furniture work.

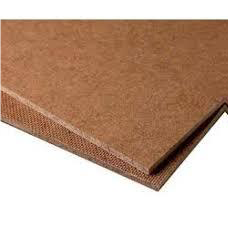

- Hard boards: These boards are made from the combination of wood waste (sawdust in Nigeria) and bonded together under high temperature and compression. They are used for making cabinets.

Advantages of manufactured boards

- They do not shrink and warp like solid wood.

- They can be worked and cut easily.

Disadvantages of manufactured boards

- They are very costly.

- Some of them have rough edges.

In our next class, we will be talking about PROCESSING OF MATERIALS – METALS AND ALLOYS. We hope you enjoyed the class.

Should you have any further question, feel free to ask in the comment section below and trust us to respond as soon as possible.