Back to: BASIC TECHNOLOGY JSS3

Welcome to class!

In today’s class, we will be talking about wood joints. Enjoy the class!

Woodwork Projects – Woodwork Joints

Woodwork machines

They are specially designed machines used for wood operations in furniture work. Examples of woodwork machines are as follows:

(i) Hand drills:

This is an electrically powered tool used for boring holes in wood. It contains the chuck which turns the drill bit clockwise and anti-clockwise.

(ii) Belt sander:

This machine is used for sanding (smoothening) the surface of the wood. Abrasive is used to coat the rollers in this electrically powered tool.

(iii) Circular saw:

The circular saw is used for cross-cutting timber, for cutting depth and for forming grooves on timber. It is electrically powered also. It can be adjusted to any desired position.

(iv) Saber Saw:

This is a flexible saw used for cutting complex shapes like curves on plywood. Like the curves found on loudspeakers.

(v) Nailing gun:

This machine is used instead of the hammer, in sticking nails into wood.

(vi) Circular sawing machine:

It is used for both crosscutting and ripping operations during woodwork.

(vii) Band sawing machine:

This machine uses the band saw. It is used for cutting straight lines, circular and irregular curves on timber and plywood.

(viii) Thickness machine:

This is the machine used for forming the required thickness for stool and table legs.

(ix) Surface planer:

The surface planer is designed for planning operations, especially planks. It can also be adopted for rebating and tenoning jobs. It has a wide, flat surface for supporting any load laid on it.

(x) Drill press:

This machine has multiple applications. It is primarily used for drilling operations, for boring holes on wood and metals. It can also be used for sanding, shaping and mortising.

(xi) Wood lathe:

This is the father of all machines. Primarily, it is used for turning operations to form table legs and lampstands or stool stands. It is used also for scraping, sanding, grooving.

Woodwork projects

Woodwork projects demand a lot of organization and planning. This is done to present a professionally finished product.

Stages in woodwork project

1. Design stage:

This is the stage where your mind conceives of a concept or an idea of what type of article you want to produce and how I will look like.

2. Drawing stage:

This is the stage where you draw your concept or idea. It could be a very simple sketch. It could be the whole article first, then the views.

3. Fabrication stage:

This stage is a combination of the working drawing and your cutting list. This list shows the dimension, quantity and description of the article.

Classes of wood joints

Wood joints are grouped into three classes, namely:

1. Box joints:

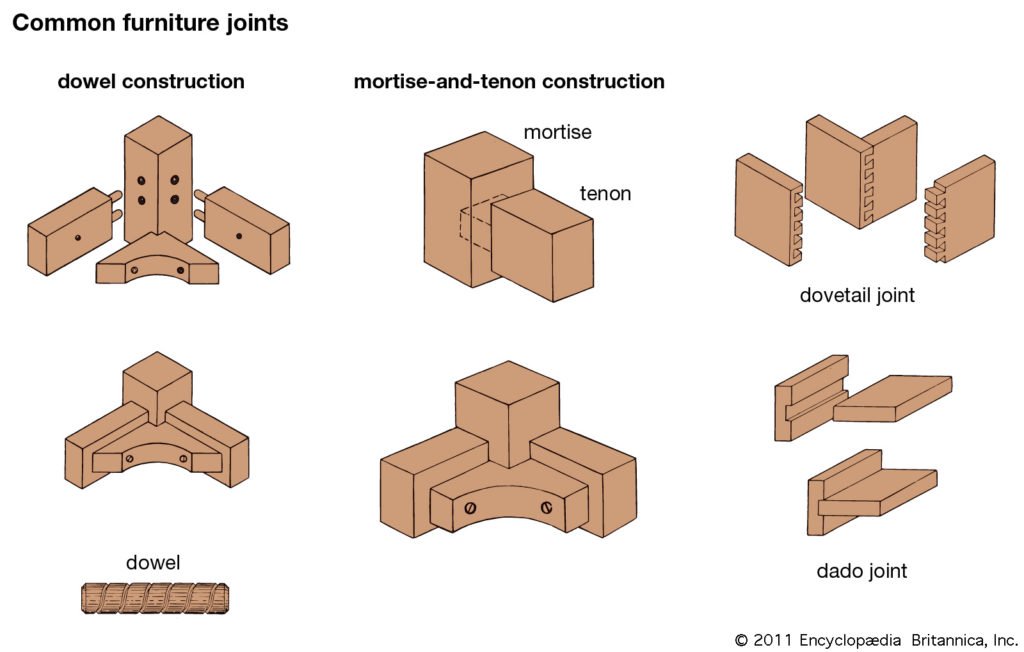

These are the classes of wood joints that form an angle of 90 degrees. They include butt and dovetail joints.

(a) Butt joint: These are joints used in the construction of boxes, window frames, roofing and cabinet products, door frames, tables and chairs.

(b) Dovetail joint: This type of joint is used for making bookshelves drawers for office tables and for making corner joints.

2. Framing joints:

These are joints that are used to form frames or network with cris-crossing endings. They include housing, halving, mortise and bridle joints.

(a) Housing and Halving joints: These are joints used for making wardrobe, chairs, table, cupboard and other articles of this nature.

(b) Mortise and Tenon Joints: These are the strongest types of joints. There is the common, haunched and bare face M&T joints. These joints are used for making a door, window frames, tables, chairs and bench legs.

3. Widening joints:

These joints are used for increasing either breath or length of boards. They include joints like tongue and groove joints, dowel joints.

(a) Tongue and Groove joints: These are joints used as floor and wall tiles in most British homes. It is mainly used for decoration.

(b) Dowel joint: Dowel joints are usually stronger and are used for cabinets and dining tables.

In our next class, we will be talking about SIMPLE WOODWORK PROJECTS. We hope you enjoyed the class.

Should you have any further question, feel free to ask in the comment section below and trust us to respond as soon as possible.

A very good teaching web

too much big nyash and penis

I love the teaching. Anytime I need help in my studies I will meet you thanks alot ☺️