Back to: BASIC TECHNOLOGY JSS2

Welcome to JSS2 Third Term!

We’ve had a remarkable journey from First term to this moment. We are going to continue our journey into the world of Basic Technology.

In today’s class, We will be discussing BELT and CHAIN DRIVE. Enjoy the class!

BELT AND CHAIN DRIVE

Belt and pulleys are used to transmit power and to provide a way of changing speeds. The simplest belt-driven device is two pulleys connected with a belt. What is said of gears also applies to pulley – “one always drives while the other is driven”. A pulley mounted on the shaft of an engine is the driver pulley. Driven pulleys are belted to the driver pulleys to operate small machines like pepper grinding machine.

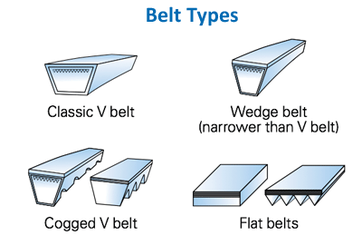

There are three kinds of belts and pulleys commonly used. They are flat belt and pulleys, Vee belts and pulleys, and variable speed pulleys, it is possible to change the speed between the driving and driven without stopping the engine.

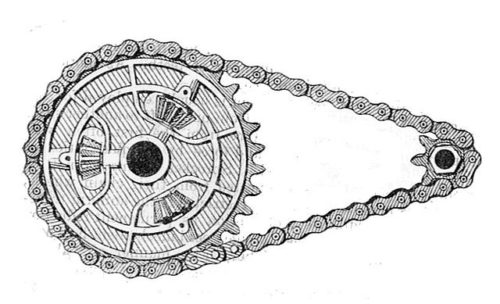

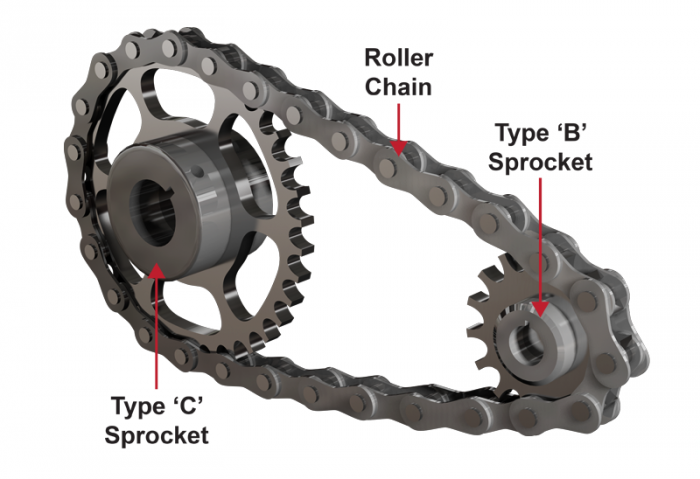

CHAIN DRIVES

Chains are often used to do the same work as a belt. It is a reliable and efficient method of transmitting mechanical power from one place to another. It is commonly used to transmit power as used in bicycles and motorcycles.

APPLICATION OF BELT AND CHAIN DRIVES

Generally, both belt and chain drives are used to transmit mechanical power from one point to another. They are used in the following ways;

- Belt is used in the pepper grinding machine, and sewing machines

- Chain is used in the bicycles

- Chain is used in motorcycles.

- Chain is used in the pulley system used for elevators.

ADVANTAGES OF BELT AND CHAIN DRIVES

- They are used in power transmission from one point to another

- They are used in speed selection and changing of speed in locomotive machines

- They are harnessed in changing of direction of rotation in machines.

- They can be used to produce smooth running at high and low speed.

DISADVANTAGES OF BELT AND CHAIN DRIVES

- Overheating may occur when there is no regular oiling.

- The driven may not function well if the belt is not firm on the pulley.

- Damage may occur when there is no proper maintenance.

Similarities between belt drive and chain drive

- Both belt drive and chain drive are mechanical drives. Thus, they utilize various mechanical elements which must be in physical contact for transmitting power. Apart from mechanical drives, other drives that are frequently used in industries include hydraulic drive, pneumatic drive and electrical drive.

- Both belt drive and chain drive are suitable for transmitting power and motion for medium to larger shaft distance. For short distances, the gear drive is preferred. However, V-belt can be applied for short to medium distance also.

- They can be applied for parallel driver and driven shafts only. They are not suitable for transmitting power between non-parallel shafts. It is worth mentioning that a quarter-turn belt can be used for non-parallel non-intersecting shafts.

- Both require frequent adjustment in tension; otherwise, slip percentage increases as the belt or chain stretch out with service time.

Differences between belt drive and chain drive

| Belt Drive | Chain Drive |

| The belt drive is a frictional type of mechanical drive where friction force between belt and pulley is used to transmit power and motion. | Chain drive is one engagement type mechanical drive where power and motion are transmitted by successive engagement and disengagement of chain with a sprocket. |

| Belt drive is preferred for medium to long center distance between the driver and driven shafts. | Chain drive can be used for short to medium center distances. |

| Although belt drive is suitable for parallel shafts, a slight parallel error is tolerable and does not create a noticeable problem. | In chain drive, parallelism must be maintained precisely, otherwise, the chain may leave sprocket without any warning. |

| Slippage occurs in belt drive when the load exceeds frictional force. | No such slippage occurs in chain drive. |

| Because of slip, the velocity ratio does not remain constant in belt drive. Thus, it is not a positive drive. | Here velocity ratio remains fixed. So chain drive is one positive drive. However, the polygonal effect may lead to non-uniformity in speed. |

| The efficiency of belt drive is comparatively low because of frictional loss. | The efficiency of the chain drive is high, usually above 95%. |

| Belt tension is affected by atmospheric conditions and temperature. Thus, the performance of the belt drive also changes with external factors. | The chain drive is usually not affected by atmospheric conditions and temperature. |

| Belt drive requires minimum maintenance. | Chain drive requires regular maintenance including lubrication. |

We have come to the end of this class. We do hope you enjoyed the class?

Should you have any further question, feel free to ask in the comment section below and trust us to respond as soon as possible.

In our next class, we will be talking about Gears. We are eager to meet you there.