Back to: HOME ECONOMICS JSS 2

Welcome to Class !!

We are eager to have you join us !!

In today’s Home Economics class, We will be discussing Garment Construction. We hope you enjoy the class!

GARMENT CONSTRUCTION

CONTENT

- Seam and Edge finishes

- Facing

- Hemming

- Crossway stripes

SEAM FINISHES

Seam finishes are basic sewing processes used to neaten the raw edges of a seam especially the open or plain seam.

Advantages of Seam finishes

- It prevents the raw edge from fraying.

- It prolongs the life span of the garment.

- It makes the garment looks neat and beautiful.

- It also gives the finished work a professional look.

Seam Finishes Processes

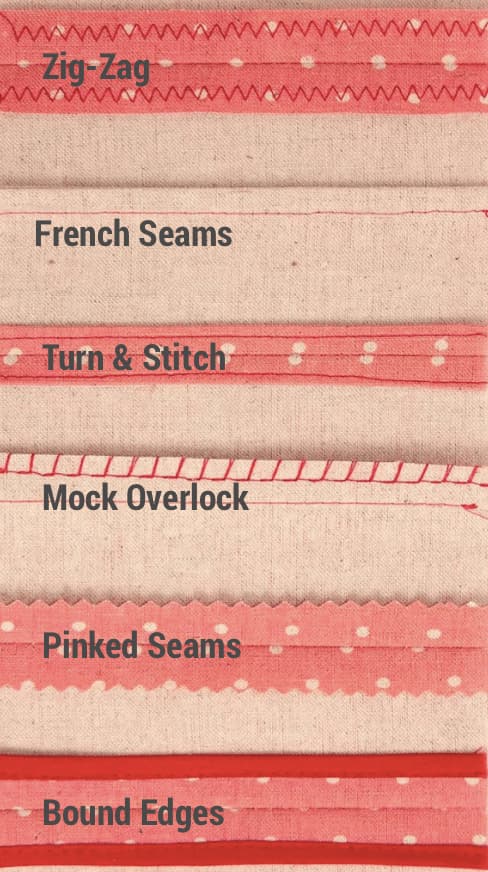

- Pinking: This is the process of neatening or finishing the seam using pinking shears. It has a zigzag edge and it is good for bulky/thick fabrics.

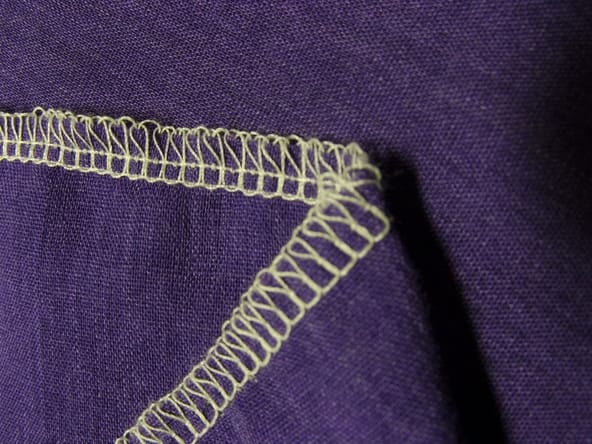

- Overcasting: It is suitable for all fabrics. It can be done with either hand or machine.

- Zigzag: It is made with a sewing machine that has a zigzag design to neaten the seam. It is suitable for all type of cloth.

- Bound seam finishing: This involves the use of bias or crossway strips. It is suitable for heavy fabrics that fray easily.

SELF EVALUATION

- Define seam finishes.

- List and explain three processes of seam finishes.

EDGE FINISHING

Edge finishing is the process of neatening the raw edge of articles or garments. Necklines, hems or low edges, waistlines of garments and skirts require different types of finishes.

Uses of Edges Finishing

- To prevent fraying of fabrics.

- To protect the edge of the fabric.

- To neaten the edge of the garment.

- To beautify the edge by using either bias or flowered material for finishing neckline and armholes.

Types of Edge Finishing

- Pink finishing

- Oven casting finishing

- Bound finishing

- Edge stitching: This is machine finishing. It is very strong and good for fabrics that fray.

- Hemming: Hemming is a method of neatening the lower edges of skirts, blouses, gowns, sleeves, etc. by folding the edge of the material to the wrong side twice and sew it up. It is not visible on the right side of the garment.

- Facing.

POINTS TO CONSIDER IN CHOOSING AN EDGE FINISHING

- The type of material or fabric to be finished.

- The shape of the edge to be finished.

- The purpose of the finishing.

EVALUATION

- State three uses of edge stitching.

- List and explain two types of edge finishing.

FACING

Facing is the process of covering the raw edge of a garment or finishing it with a piece of fabric. Facing shows on only one side of the garment.

When facings are turned to the wrong side, they are not seen from the right side. This is called inside or inconspicuous facing. When they are finished on the right side of the garment, they are called conspicuous or decorative facings.

Uses of Facing in Garment Construction

- For covering the raw edge of a garment.

- To reinforce the garment edge and retain its shape.

- To decorate a garment, when it is applied on the right side.

SELF EVALUATION

- Differentiate between conspicuous facing and inside facing.

- State three points to consider in choosing an edge finishing.

GUIDELINES FOR ATTACHING FACING

- Facing should be cut to the same shape as the edge of the garment to be faced.

- The width of the facing should always be enough to give a neat, flat finish.

- If facing is to show on the right side, put the right side of facing to the wrong side of the garment.

- If facing is to appear on the wrong side, place the right side against the right side of the garment.

TYPES OF FACING

- STRAIGHT FACING: This is used on straight hems or front of button-through skirts. Straight facings are cut on the straight line of the fabric with the edge to be faced quite straight.

- SHAPED FACING: This is used on a curved edge. The facing is cut to fit exactly the shape of the edge to be neatened. It is often used for armholes of sleeveless garments, necklines of collarless garments, V-necklines, etc.

SELF EVALUATION

- State three guidelines in attaching facing.

- List and explain the two types of facing.

CROSSWAY STRIPS

Crossway strips are bands of fabrics cut on the diagonal line of a squared fabric at 45º. The crosswise grain is folded on the lengthwise grain and this forms a true bias. They are used for binding raw edges, facing raw edges, bound buttonholes, piping, neatening and decorating garments.

STEPS IN THE CUTTING OF CROSSWAY STRIPS

- Fold the material across so that the selvedge threads lie across and parallel to the weft threads.

- Pin the material together a few inches away from the fold.

- Firmly hold the material with the left hand and cut along the fold. The cut edges are true cross from which stripes can be cut.

- To cut the crossway strip measure out the width of the strip required at right angles to the edge. Mark the width with tailors chalk along the length of the strip. Cut along the marked line

JOINING CROSSWAY STRIPS

- Lay out the strips side by side.

- Cut the ends parallel to the selvedge edges.

- Place the selvedge edges together with the right sides facing.

- Tack and stitch.

- Remove basting and press open the seam allowance.

- Trim off the protruding corners.

GENERAL EVALUATION QUESTIONS

- Differentiate between seam finishes and edge finishing.

- List and explain three methods of finishing seams.

- List and explain types of seams.

- State three uses of edge finishing.

- List and explain five types of fastenings.

We have come to the end of this class. We do hope you enjoyed the class?

Should you have any further question, feel free to ask in the comment section below and trust us to respond as soon as possible.

We have come to the end of this term and hence JSS2. It’s been a remarkable journey and we are glad that you have made it this far. For making it this far, we commend you for being resilient, you have taken charge of your education and future.

The Journey still continues though, we are moving on to JSS3. we hope to meet you there.

use illustrations please for better understanding